Rubberwood vs. Eucalyptus Plywood: Which Wood is Better for Thai Construction?

[Introduction: The “National Wood” vs. The Challenger]

In Thailand, Rubberwood is known as the “Ivory Wood.” It is the darling of the local furniture industry, and rightly so—it’s abundant, cheap, and has a nice grain for table legs and chairs.

But as a professional buyer, you might have faced its limitations: Rubberwood Finger Joint Boards warping in the rainy season, color variations in large panels, or lack of strength in long-span structures.

While Rubberwood is great, it is not a “do-it-all” material.

At The Plywood Hub (China), we introduce you to its powerful rival from the north: Eucalyptus (Hardwood). Today, through a fair technical comparison, we show you when to switch to Eucalyptus Plywood to solve the problems Rubberwood can’t fix.

Round 1: Strength & Toughness (Structural Integrity)

-

🏆 Rubberwood (The Furniture Wood)

Rubberwood is a medium-density timber. It is somewhat brittle. Because it is high in sugar/starch, it is prone to insect attacks if not heavily treated. It is excellent for solid wood components like legs and frames but weaker in thin sheets.

-

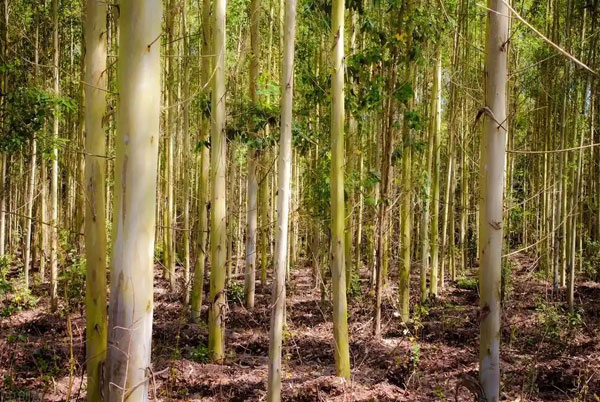

🏆 Eucalyptus (The Structural Wood)

Eucalyptus is a famous High-Density Hardwood (Density 600kg/m³+). Its fibers are long and extremely tough.

The Winner for Construction: Eucalyptus

In high-rise concrete casting, Eucalyptus plywood can withstand immense side pressure without bursting. Its toughness far exceeds that of brittle Rubberwood finger joints. This is why 90% of high-rise formwork uses Eucalyptus.

Round 2: Water Resistance & Stability

-

💧 Rubberwood

Rubberwood Finger Joint Boards are made of thousands of small wood blocks glued together. This means thousands of joints. In Thailand’s humid monsoon season, these joints absorb moisture unevenly, leading to surface waviness or “telegraphing.”

-

💧 Eucalyptus Plywood

Our Eucalyptus plywood uses a “Cross-Laminated” structure (layers placed perpendicular to each other). This structure naturally cancels out internal stress. Combined with Phenolic WBP Glue, its dimensional stability in humid conditions is far superior to Rubberwood.

The Winner for Wet Areas: Eucalyptus

Ideal for bathroom vanities, kitchen cabinets, and wall substrates in humid zones.

Round 3: Size Flexibility

-

📏 Rubberwood

Limited by the small diameter of the rubber tree log, it mostly comes as “Finger Joint Boards” in fixed standard sizes (like 4×8). Finding a large, seamless sheet bigger than 4×8 is difficult or expensive.

-

📏 Eucalyptus Plywood

Using rotary cut technology, Eucalyptus logs are peeled into huge continuous veneers. We can easily produce 4×8 ft, 4×10 ft, or even larger seamless sheets with no joints on the face.

The Winner for Large Panels: Eucalyptus

Perfect for tall wardrobe doors, partition walls, and conference tables where you need a large, smooth substrate for lamination.

Round 4: Cost Efficiency

-

💰 Rubberwood

Although local, the price of high-grade Rubberwood in Thailand has been rising due to export demand. Plus, the “waste factor” in processing irregular solid wood is high.

-

💰 Eucalyptus

China possesses the world’s largest plantation Eucalyptus base, with a hyper-efficient supply chain. Through The Plywood Hub’s direct factory connection, the landed cost (CIF) of Eucalyptus plywood is often more competitive than equivalent grades of local Rubberwood.

The Winner for Mass Production: Eucalyptus

[Conclusion: The Best of Both Worlds]

We are not saying you should abandon Rubberwood. For solid wood feel, it is irreplaceable.

Our advice is to adopt a “Hybrid Strategy”:

Use Rubberwood for:

- ✓Table legs, chair frames, moldings (parts you touch and see)

Use Chinese Eucalyptus for:

- ✓Cabinet carcasses, large back panels

- ✓Drawer bottoms, concrete formwork

- ✓Parts that need strength, stability, and cost control

The Plywood Hub (China) — Reject Middlemen, Connect Direct to Factory.

Let us help you mix and match the best wood species for your project to maximize performance and profit.