Factory View: Not Every 72h-Boiled Board is BS1088. Here is the Truth.

[Introduction: The “Marine” Confusion]

If you walk into a Linyi plywood factory with me, you will see thousands of boards that look exactly the same. They are all black or brown, and they all smell like fresh glue.

For a buyer in Thailand, distinguishing between a “Standard Waterproof Board” and a “True Marine Board” is nearly impossible just by looking. I have seen too many contractors pay top dollar for “Marine Grade” plywood, only to find it swelling on a Phuket dock six months later.

Why does this happen? Because in the industry, the term “Marine” is often used loosely as a marketing buzzword for anything with waterproof glue.

At The Plywood Hub, we don’t play word games. Today, I want to take you behind the scenes and explain what actually happens in the production line that makes a board worthy of the BS1088 Standard.

1 The “Boil Test” Reality: 10 Hours vs. 72 Hours

Many suppliers will promise you: “Don’t worry, this is WBP glue, it’s waterproof.”

But “Waterproof” has levels.

In our alliance factories, we run boil tests every day.

The Standard Board:

Uses Melamine WBP. It survives about 10-15 hours in boiling water. This is great for a bathroom vanity, but it is NOT Marine grade.

The BS1088 Board:

We use undiluted Phenolic WBP. We boil these samples for 72 hours continuously. Sometimes, we even keep them boiling for a week. The wood might start to soften, but the glue line? It remains rock solid.

💡 My advice:

If a supplier cannot show you a video of their board surviving a 72-hour boil test, do not use it for your yacht or exterior project.

2 The Hidden Killer: Core Voids

You might ask, “If the glue is good, the board is good, right?”

Wrong. The biggest enemy of marine plywood isn’t the glue; it’s the air pockets (voids) inside.

In lower-grade production, workers might overlap veneers or leave gaps to save time. In a dry house, this is fine. But on a boat? That tiny air pocket will expand when it gets hot and contract when it gets cold. Eventually, it sucks in moisture like a vacuum.

Our Filter Process:

For our BS1088 orders, we require factories to use a “Light Box” inspection. Every single sheet of core veneer passes over a bright light to check for holes before it goes into the press. If there is a hole, it gets rejected. This ensures the board you receive is 100% solid wood, through and through.

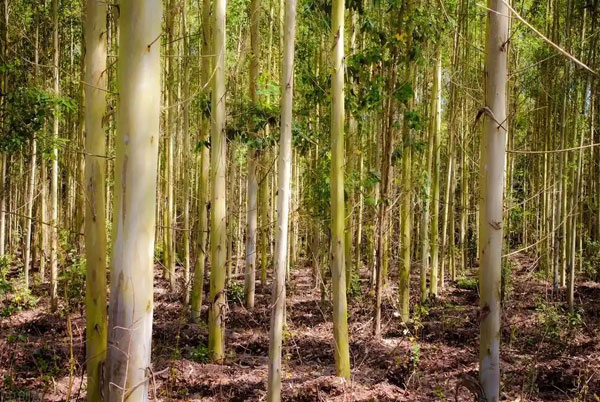

3 Why We Recommend Eucalyptus for Thailand

Traditionally, people think Marine Plywood must be made of expensive tropical species like Keruing or Meranti.

But let’s look at the data.

China’s Eucalyptus (Hardwood) has become a game-changer.

- • It has a density of over 600kg/m³.

- • It is naturally oily, which helps repel water.

- • Most importantly, it is sustainable and affordable.

Through The Plywood Hub, we have successfully replaced expensive Indonesian marine boards with Chinese Eucalyptus Phenolic boards for many Thai boat builders. The performance is identical, but the cost is 30% lower.

4 How to Inspect Like a Pro?

When your container arrives in Bangkok, don’t just count the pallets. Do this:

- • Look at the Edge: Is it “clean”? A true marine board has very distinct, straight layers. If the lines look wavy or messy, the pressure during manufacturing was uneven.

- • The Sound Test: Knock on the center of the board. It should sound sharp and crisp, like knocking on a solid door. If it sounds dull or hollow, there is a void inside. Reject it.

[Conclusion: Transparency is the Best Policy]

We are not just selling you a piece of wood; we are selling you the assurance that your project won’t fail.

Whether you are building a luxury pier or a simple outdoor kitchen, you deserve to know what you are buying.

The Plywood Hub (China) exists to bridge the gap between “Marketing Claims” and “Factory Reality.”

Need a quote for genuine BS1088 boards?

Connect with us directly. We will show you the lab reports, the boil tests, and the real factory price.